These strangely-shaped twisted-toroid propellers look like a revolutionary (sorry) advance for the aviation and marine sectors. Radically quieter than traditional propellers in both air and water, they’re also showing some huge efficiency gains.

Propellers are designed to take a fluid, generally air or water, and use a rotating motion to push that fluid through. They’re evolutions, in a sense, from the Archimedes’ screw, which was likely used in ancient Egypt thousands of years before it was described by Archimedes in 234 BCE.

For devices designed to revolve, however, there’s been little in terms of revolutionary design changes for an awfully long time; prop-driven aircraft still use twisted-aerofoil bladed props similar in design to the bamboo-copters Chinese kids were enjoying 2,400 years ago, with surprisingly slim gains in efficiency over the wooden props the Wright brothers developed in wind tunnels in 1903. Boats still use screw-style propellers, variants of which can be found as far back as the 1700s.

So we’re fascinated to find a couple of groups claiming they’ve demonstrated significant advantages in both air and water using a markedly different shape – specifically, strange twisted-toroid ring shapes that appear not only to be much, much quieter than traditional designs, but so much more efficient, particularly in the marine space, that they could mark a profound leap forward.

A potential game-changer in the air

One key issue with multicopter props is their annoying noise, which is often described as “whiny,” because much of it sits right in the same frequency range as a baby’s cries. Humans tend to be most sensitive to sounds between around 100 Hz and 5 kHz. This makes evolutionary sense; it’s where we hear vowel sounds that are key to verbal communication. But it’s a key issue if multicopters are going to fulfill their potential and fill our skies with fast, cheap, clean aerial delivery services. Residents and lawmakers don’t want to add more annoying noises to urban life.

A team working on a silent, ion-propelled plane at MIT’s Lincoln Laboratory found itself wondering whether prop noise in multirotors could be mitigated with differently-shaped propellers.

“Propellers, as we know, are pretty loud,” says Dr. Thomas Sebastian, a senior staff member in the Lincoln Lab’s Structural and Thermal-Fluids Engineering Group. “And we can look at wings to see how that works. Back when people were coming up with all kinds of crazy ideas for airplanes in the early 1900s and during World War 2, there were a couple of designs that were basically these ring wings. So I wondered what it would look like if you took a ring wing and turned something like that into a propeller.”

“We came up with this initial concept of using a toroidal shape, this annular wing shape, to hopefully make a quieter propeller,” Sebastian continues. “I had an intern of mine, who was just absolutely phenomenal, run with the idea. He took the concept and created a bunch of iterations using 3D printers.”

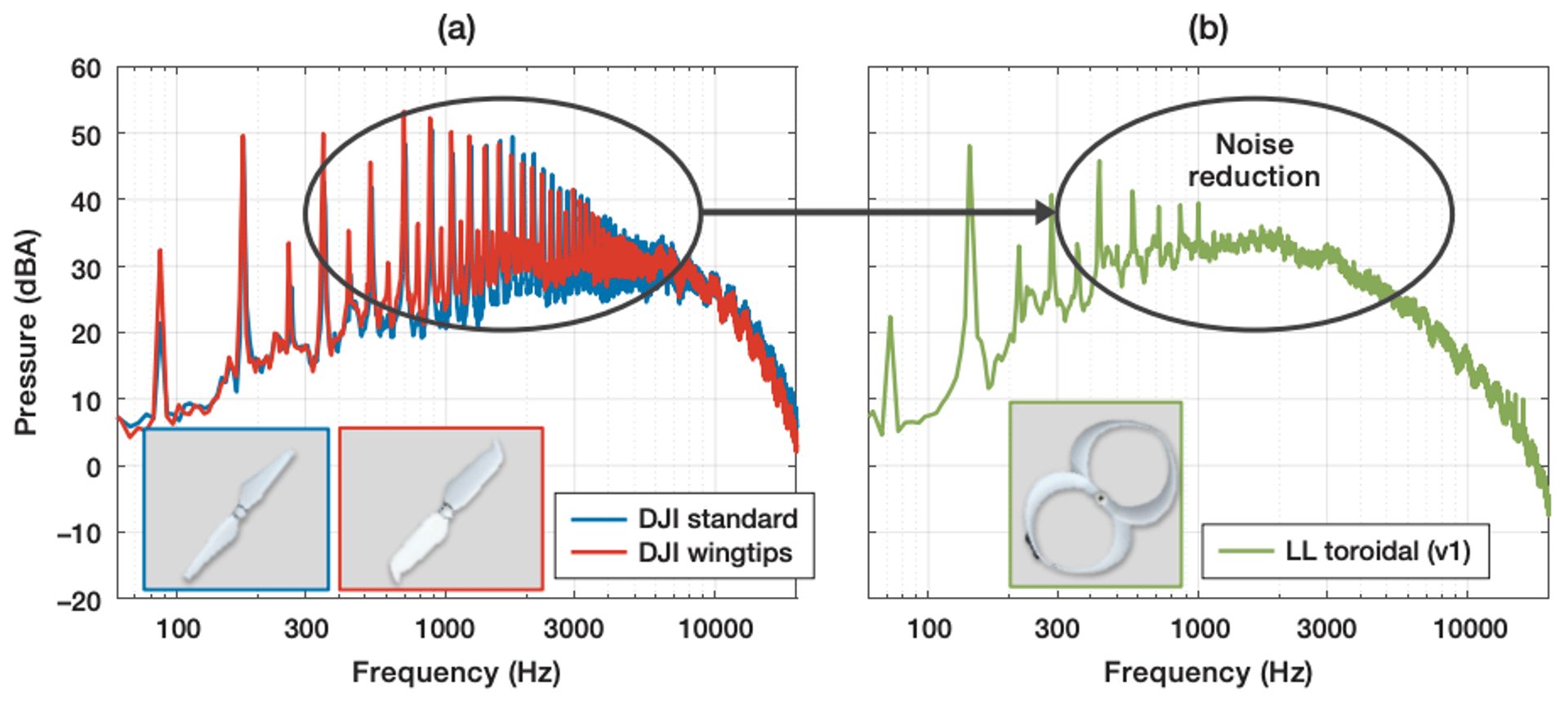

Within a few attempts, the team indeed found a design that reduced not only overall noise levels at a given thrust level, but particularly noise in the 1-5 kHz range.

Indeed, they sound more like a rushing breeze than a propeller, making a much less intrusive sound. Anecdotally, according to the team, a drone running these props makes a level of sound roughly as annoying as a regular drone about twice as far away. Have a listen in the video below:

“The key thing that we thought was making the propellers quieter, was the fact that you’re now distributing the vortices that are being generated by the propeller across the whole shape of it, instead of just at the tip,” says Sebastian. “Which then makes it effectively dissipate faster in the atmosphere. That vortex doesn’t propagate as far, so you’re less likely to hear it.”

Propeller noise can be somewhat addressed by placing rings of acoustic treatment around the circumference of a prop’s path, which can also act as prop guards from a safety perspective. But these add parasitic mass, reducing battery life, and they can also catch the wind in outdoor situations, making the drone work harder to stay stable.

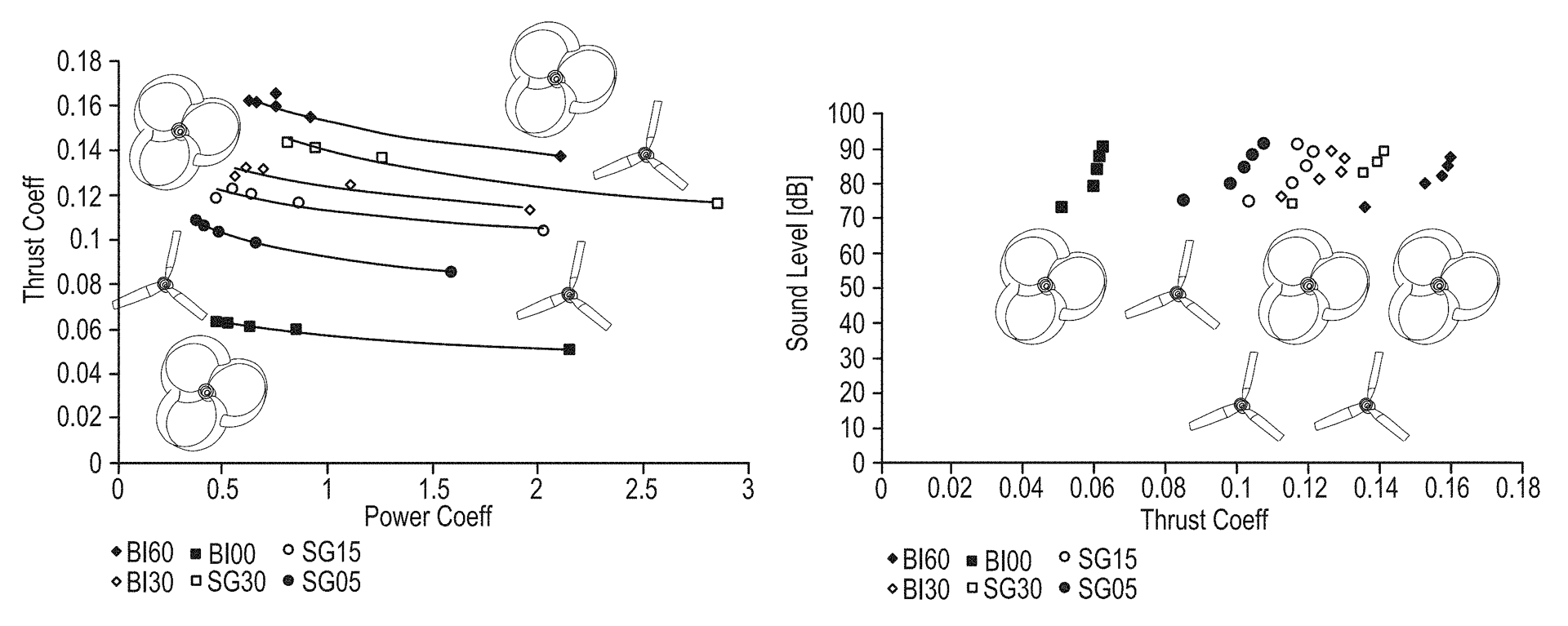

The team analyzed these weird-looking toroidal props to see whether there would be a thrust efficiency penalty. Apparently not: the team’s best-performing B160 design was not only quieter at a given thrust level than the best standard propeller they tested, it also produced more thrust at a given power level – pretty remarkable given that standard props have more than a century of development behind them and these toroids are at a very early stage, with plenty of optimization yet to come.

What’s more, their looped shape not only adds structural stability, but decreases the chance of a prop cutting, clipping or catching on things it runs into. You’re still not going to want them hitting you in the face, but there’s probably a marginal safety improvement there.

In terms of drawbacks, these are fairly complex shapes, so they’re much harder to manufacture than standard props using cheap and easy injection molding. They’re probably the sort of thing you need to get 3D printed. But even if they double or triple the price of propellers, these are a low-cost part of a drone and the overall impact might not be that tough on the hip pocket.

It’s unclear at this stage whether designs like this might be relevant at a larger scale, replacing traditional propellers on fixed-wing aircraft, or indeed on electric VTOL air taxis. The latter already appear to be significantly quieter than helicopters, but if they end up flooding the urban airspace with fast, cheap, green aerial transport, every decibel of noise will count when it comes to public and regulatory resistance. The question there, really, is what kind of frequencies these larger props will occupy in the audio spectrum, and whether the toroidal props shift the sound in a human-friendly direction.

The team has patented the design, and while it’s not clear whether there are plans to commercialize it, MIT appears to be prepared to license it to interested manufacturers.

An even bigger advantage in the water

Drones and aviation are one thing, but aerodynamics and hydrodynamics are closely related, and it turns out there’s already a product close to production in the marine space that takes a very similar approach.

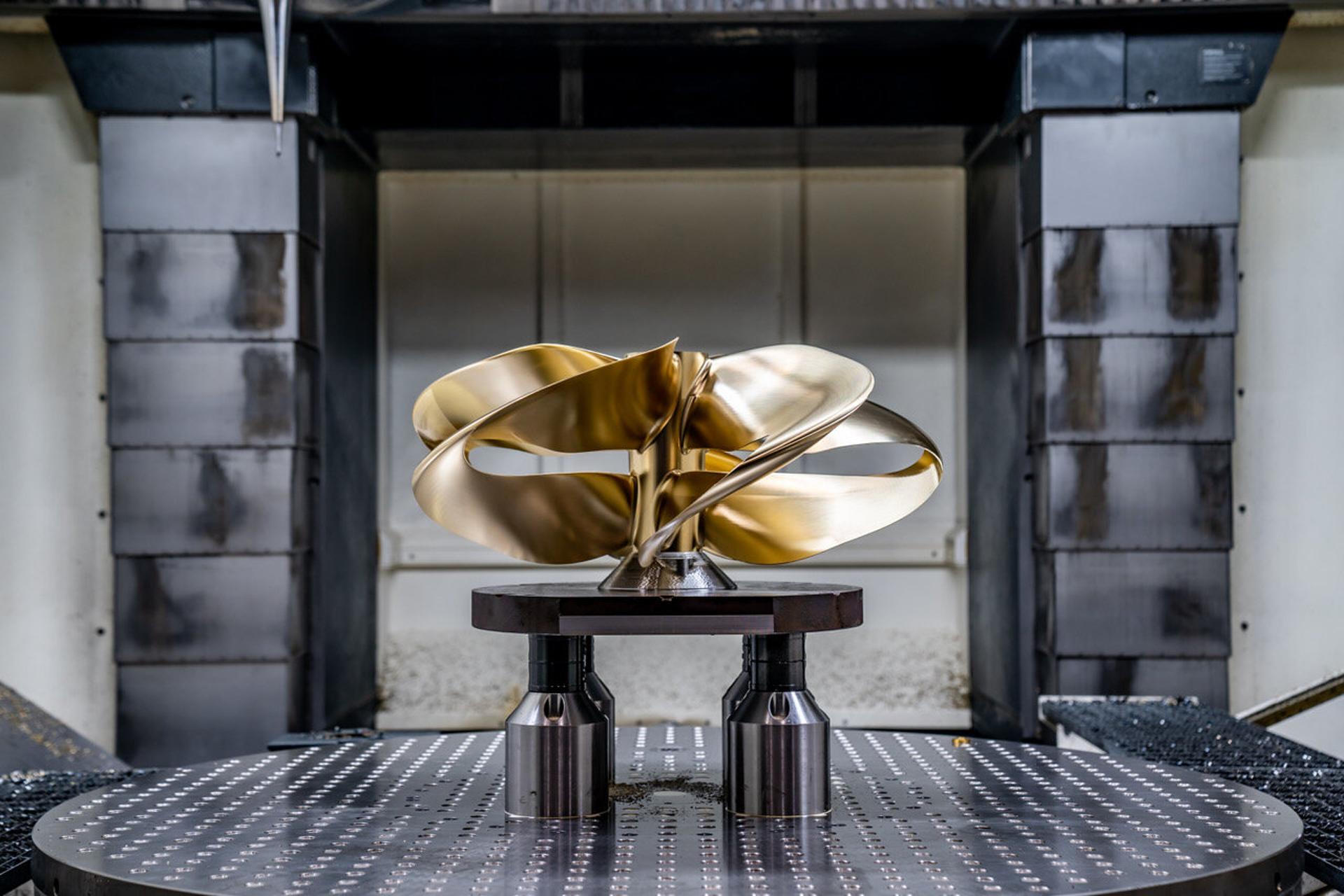

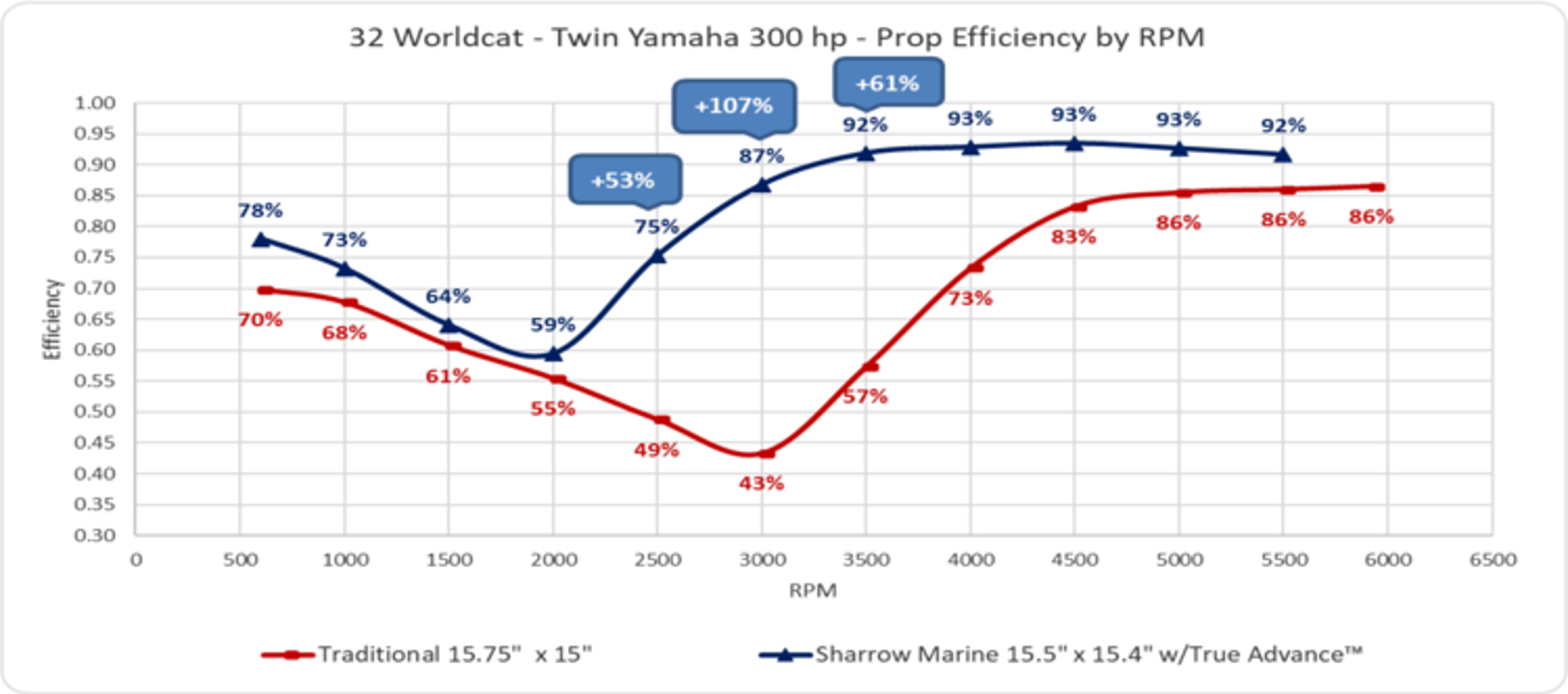

Sharrow Marine has been getting frankly spectacular results from boat propellers that use toroidal loops instead of standard blades. After several years of development, the company has now tested its props against hundreds of standard propellers, and the difference is incredible. Sharrow’s props simply don’t create tip vortices – a major source of energy loss and a surprisingly large component in the overall noise of an outboard engine.

Vastly reducing the amount of fluid that “slips” out the sides of a propeller rather than being pushed through, the toroidal props suck more water through, and advance a boat further, per turn. They regularly double the speed a boat can achieve at lower and mid-range RPMs, radically broadening the effective rev range of the motor. And they reduce fuel consumption by somewhere around 20% – a seriously big deal given the huge energy requirements of propeller-driven boats and the scale of the industry.

Sharrow says they have the interesting effect of vastly reducing a boat’s tendency to pitch backward as it accelerates; instead, the entire boat rises out of the water while staying much more level. On top of all this, the effect on noise is absolutely profound, as you can see in the video below.

Standard vs Sharrow MX™ Noise Comparison

Indeed, the company says this is a propeller you can stick on more or less any outboard motor, then blast along at 30 mph (48 km/h) quietly enough to have a conversation on board without raising your voice. Remarkable stuff.

Sharrow is already selling its toroidal props, CNC machined to fit a wide range of common outboard motors from most major manufacturers. The drawback here is price; they cost US$4,999 a pop regardless of which model, where a regular propeller might go for closer to US$500. But again, this is a pretty small component in the overall cost of many boats, and given their voracious appetite for fuel, the outlay may well pay for itself in short order as well as making the ride a lot more comfortable for the people on board, bystanders, and for marine life under the surface.

In the age of the energy transition, these things must also be of extreme interest to anyone making electrified boats, where a 20% boost in range from a five-grand accessory would be an absolute no-brainer. Check out a fairly concise presentation from Sharrow in the video below.

The Sharrow Propeller™ EXPLAINED

Sources: MIT, Sharrow Marine